Deepen your design standard workflow witha 30-minute command

Focus on deepening the design of the work content, deepening the design work in the difficulties and we chat about deepening the role of the whole decoration project.

01

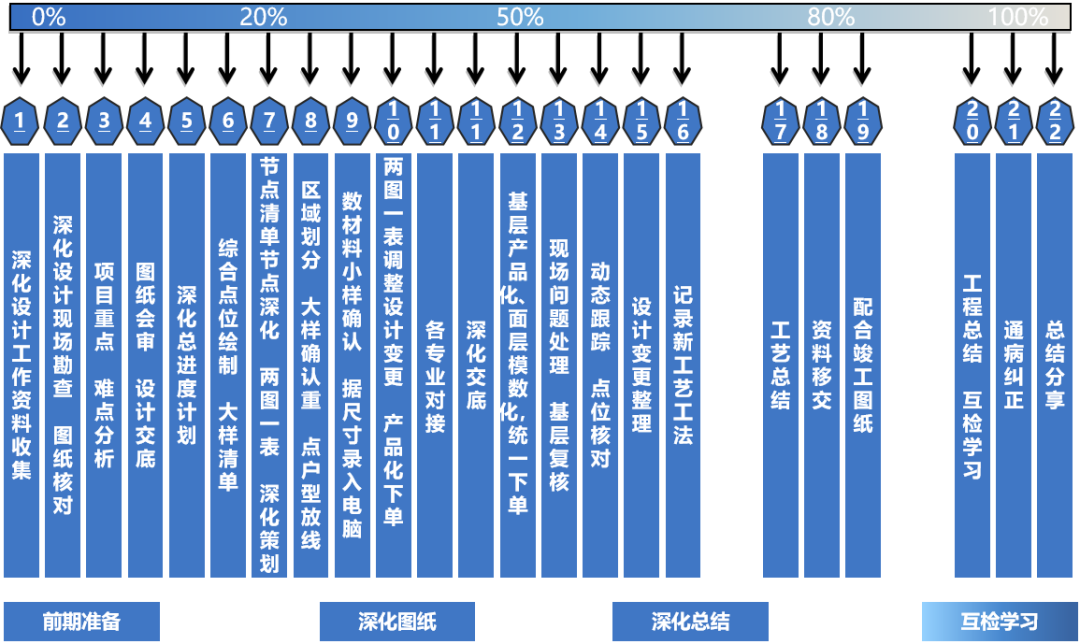

Deepen the overall process of design

Deepen the main responsibilities of the planning staff

There are many types of deepening work, and different types of engineering projects need to be deepened. Simple can be summed up as:

The deepening design department needs to make the deepening schedule according to the project’s work plan and schedule plan

Deepen the designer needs to cooperate with the project department to carry out drawing triage, on-site changes, technical approval;

The cooperation, correction, and data input of the pre-release line are entered into the computer, to place the order and verify in the future;

To deepen the grass-roots level of the site, surface with the manufacturers to deepen, the formulation of different materials and processes of the closing program;

Draw layout, comprehensive layout (top, wall, ground), and check site correction;

List the design answer form, material form, size sample list, drill-down node list, process control form, related units with the form, with two figures and one table.

02

Deepen the work schedule of the design phase

Bid match / project operation / process node / full case landing …

2.1

Start thinking about project deepening

Project: coordinate arrangements to deepen personnel.

Pre-planning: clear deepening direction, how to carry out the project to deepen the work of thinking. Through the visit to the boutique project, analysis of the project focus and difficulties, the focus, difficult drawings to guide the idea.

“532” method

50% is the time to finalize the program, material confirmation, details of deepening and custom product orders;

30% of the time in the supporting plant processing;

20% of the time for on-site assembly, inspection, delivery.

Comprehensive review: Due to the different project duration, quality positioning is different, the content of the deepening will also make some adjustments. Combined with the views of the project manager, budget manager, and material manager, what kind of deepening steps and progress are appropriate for the project, deepen the focus of control.

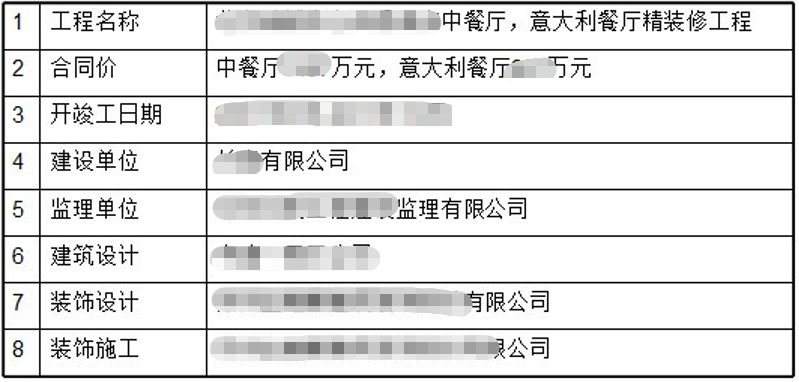

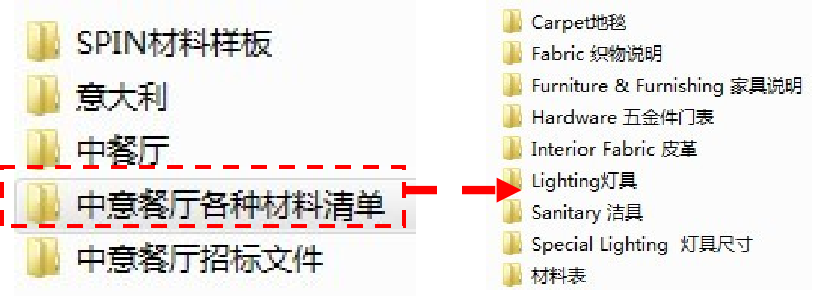

Information collection: understand the relationship between owners, general packages, supervisors, position, and role in the project, analyze the characteristics of the project and competitors. Collect local laws and regulations, engineering construction technical specifications, analysis of drawings to inspect the site, familiar with the owner’s quality requirements: such as Yangzi Cup, Luban Award, etc., and according to the server upload information (missing information part with a text description).

2.2

Project preparation phase: coordinate communication

Picture Paper finishing: Collect upstream design drawings.

Small sample finishing: Understand the owner’s investment budget, through the finishing of upstream designer material samples, understand the design intentions of upstream designers.

Project communication: Learn more about the status of the project, the cost of the project contract, and the duration.

2.3

Deepen the early-stage work

Basic information: Sign up for the basic information of the design unit (e.g. civil engineering, mechanical and electrical, HVAC, fire protection, kitchen, swimming pool, meeting, and other drawing materials).

Audit drawings: The designer, owner, supervisor, and construction party jointly review the upstream design drawings, find out the unreasonable parts that may exist in the construction process, form a unified written form after discussion by the project department, and propose amendments to the owner to facilitate the construction progress control of the project department.

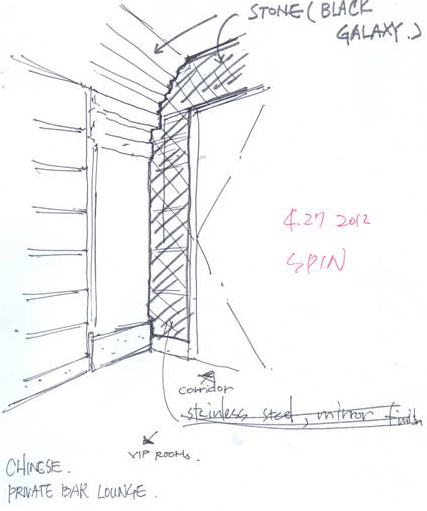

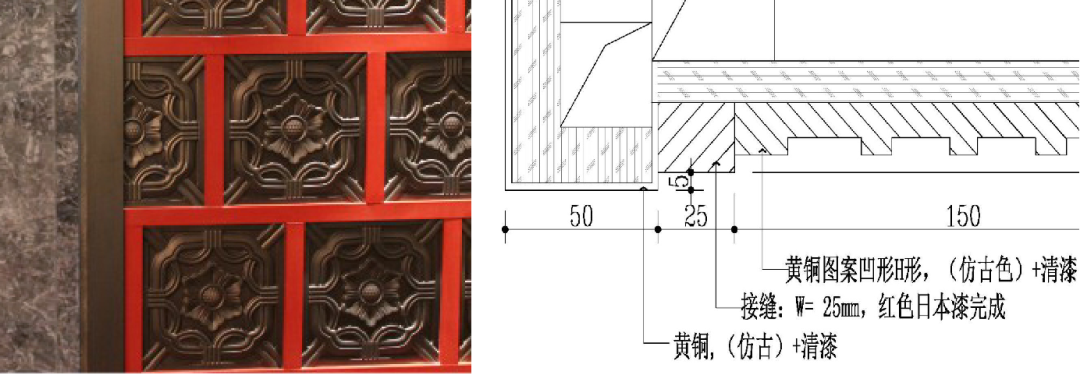

Understand the upstream designer’s intention in each space, stone, wood finish, copper shape and other closing practices, the specific materials, and installation methods;

Design the bottom record sheet;

Drawing triage records;

Regional division: in collaboration with the project department to read the map, participate in the project department construction planning, and the project department to jointly agree on the scope of productized zoning, with the budgeter to discuss the project profit and loss point, to develop a reasonable business strategy;

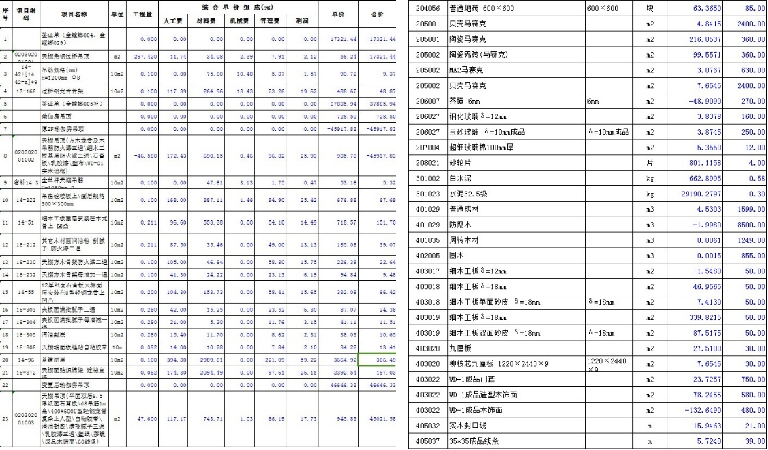

Docking with the pre-final accounts, master the project’s main grass-roots materials, surface materials profit and loss situation, understand the deepening of the profit space, such as nodes to deepen the basic material specifications model, spacing, surface loss materials through and design and owner communication after the development of design changes profit opportunities.

On-site review: Review site size, elevation, pipeline, pipe well, etc.

2.4

Product deepening phase: itemized quantification

Confirmation process: productized partition construction drawing output to do the schedule, confirm the grass-roots, surface-level practices, clear process nodes, all kinds of materials, the project complete construction (including integrated mechanical and electrical points) drawing plan.

: Replanting plan: When the owner agrees and time permits, the missing drawings are communicated with the project budget officer promptly. Find out the difference with the blueprint map, make the first version of the design changes, for the site to do the pen.

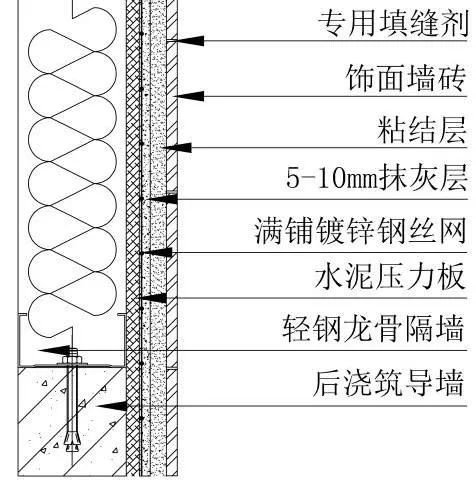

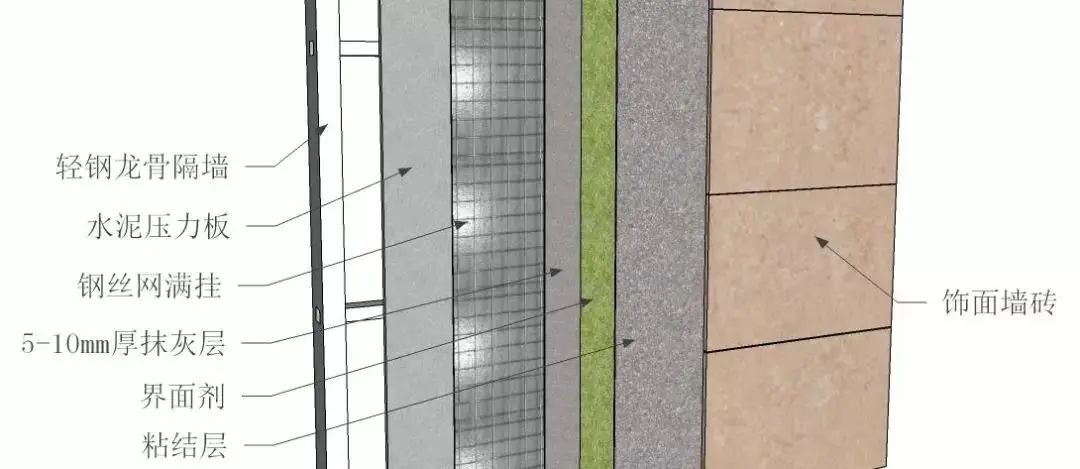

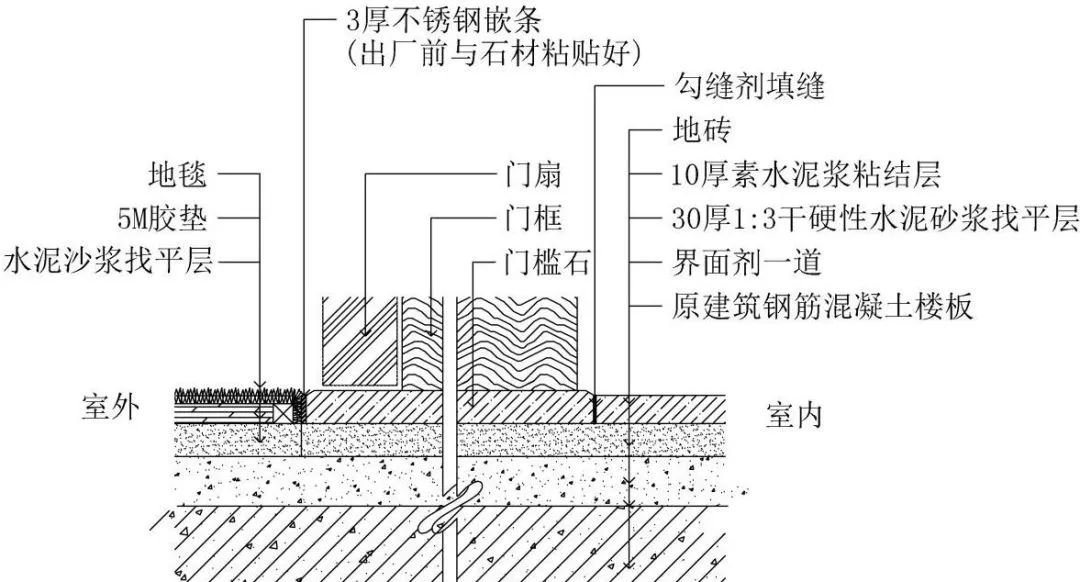

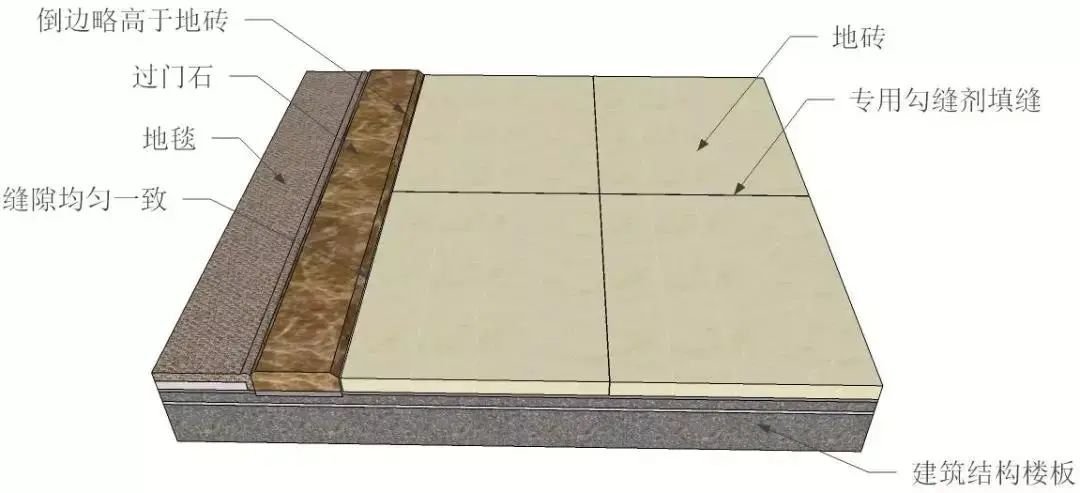

General nodes: finishing partition walls, surfaces, closings, and other common practices.

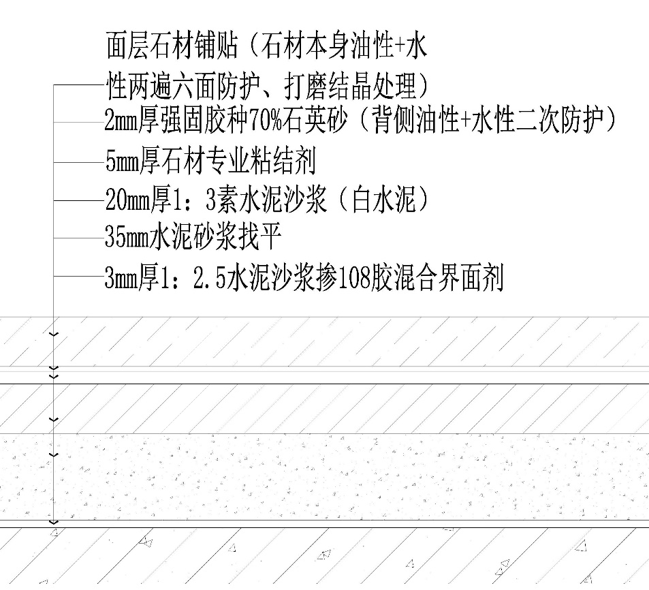

Solid wall tiles are mounted ☟

Light steel keel partition wall tiles are mounted ☟

Floor tiles paved with threshold stone outlet ☟

Comprehensive smallpox finishing: actively work with the relevant units to draw a comprehensive smallpox map, combined with the construction site layout finishing line, confirm the lighting, spray, air vents, access to the location rationalization, control the overall layout reasonable, beautiful. (Comprehensive smallpox drawings need to be signed by the owner and related units).

Top-faced integrated cloth point:

1, determine the ceiling height and material

2, lamps

(1) Light drawings are integrated into the composite top surface drawings;

(2) Lamp replacement, in the construction of replacement lamps should be noted as follows:

a: whether it is a dimming system to determine the type of transformer;

b: Do not change the type and power and color temperature of the lamp cup;

c: According to the change of lamps, adjust the distance between the lamps and the wall and review whether the space of the on-site ceiling is suitable for the installation of certain types of lamps, pay attention to the area to be anti-glare;

d: Replacement of hidden lamps: LED belt, cold cathode tube, T5;

(3) Fire equipment:a:spray,b:smoke,c:temperature,d:fire broadcast,e:fire curtain

(4) HVAC equipment:a:air outlet,b:return air vent,c:wall smoke,d:ventilation fan,e: new airvent,f : Access port

(5) Weak power equipment:a:camera,b:lift projector,c:background music broadcast,d: network

(6) Stage equipment:a:stage lighting,b:control equipment,c:electric curtain,d: lifting benchmark,e: otherconference systems

Mechanical and electrical drawing finishing: wall integrated distribution points, strong electricity, weak electricity, intelligence, conference system design, sound system, fire, HVAC, water supply and drainage, dimming, and other professional units to coordinate, confirm the endpoint drawing confirmation, the implementation of site location positioning.

Ground integrated cloth point drawing

1, the steps and methods of the ground integrated cloth point with the top surface integrated cloth point;

2, need to pay attention to the surface point has a special shape position, to communicate with the designer promptly;

3, need to pay attention to the ground finish layout after the fixed point (example: the location of the ground leakage point and center or in the corner, the opening position of the toilet, ground socket, etc.);

4, picture analysis:

The wall is drawn with a composite cloth point

1, the steps and methods of the wall integrated cloth point with the top surface integrated cloth point;

2, need to pay attention to the wall point has a special shape position, to communicate with the designer promptly;

3, pay attention to the wall layout after the fixed point (example: point height and size, centering, the upper mouth flat, the lower mouth equal);

4, some need to pre-buried wall point;

5, picture analysis:

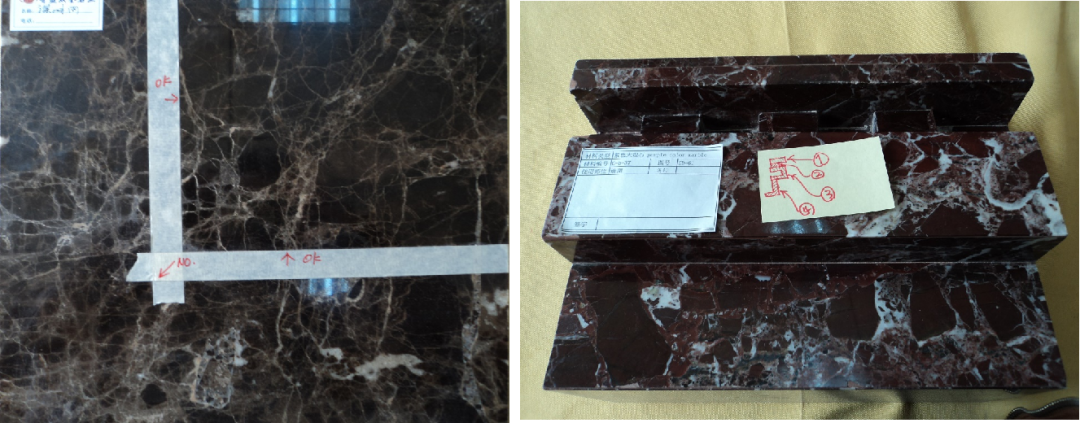

With the material signature: first by the upstream designer to provide a complete sample of the material, with the project department in the country to find real samples or alternatives, the production of material models, for upstream designers to confirm.

2.5

Deepen the medium-term work

On-site review: For wood and stone deepening, hydropower point, lamps completed deepening drawings, on-site review, positioning.

Drawing changes: timely integration of site construction drawings, communication with upstream designers and owners of the designers, finding problems timely changes, by upstream design, the owner signed confirmation. The reasons and contents of the change need to be documented in detail, taking into account whether it has an impact on other areas.

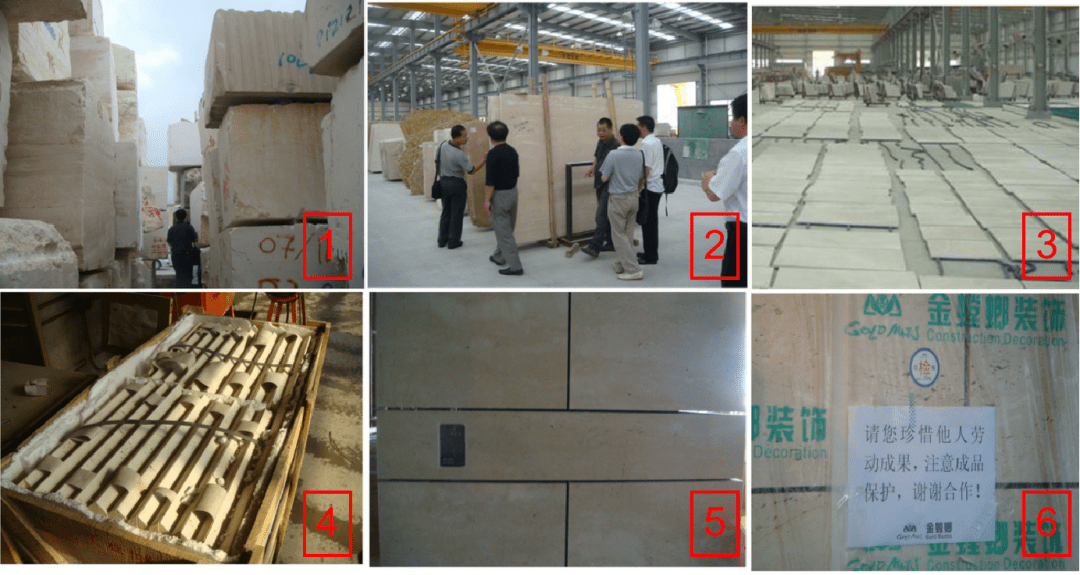

Product order: audit the professional manufacturers under the single drawings (wood finish, stone, copper, aluminum plate, GRG and other materials, clear number (house type, floor number, façade) layout requirements uniform specifications and strive to mold, productization.

Closing: Clear closing details practices, combined with their own experience, in communication with the project department, improve the details of the practice, to assist the project department according to the drawing construction.

2.6

The product is in the order stage

On-site coordination: According to the project difficulties, focus on the construction process, remind the project department to pay attention. For the wood and stone deepening, the hydropower point has been completed the deepening drawings, the review, and positioning.

Drawings on the wall: the construction site key parts of the effect map and construction drawings need to be pasted on the wall, with the progress of the project to replace the drawings, is conducive to better guide the construction of the site workers.

Description of wall materials, drawings bonded to wall surfaces

Business node deepening: to ensure the quality of the project at the grass-roots level, as far as possible to choose conducive to the construction program and more complex construction process, for the project department in the auxiliary materials and group prices to win the maximum profit. To deepen the nodes and practices operated in the drawings, to enlarge the practice reasonably, and to reduce the practice reasonably.

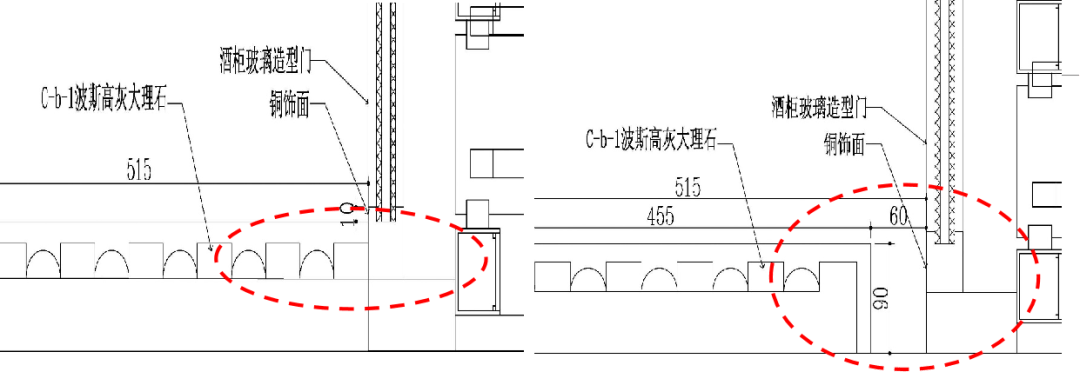

Stoneground practices

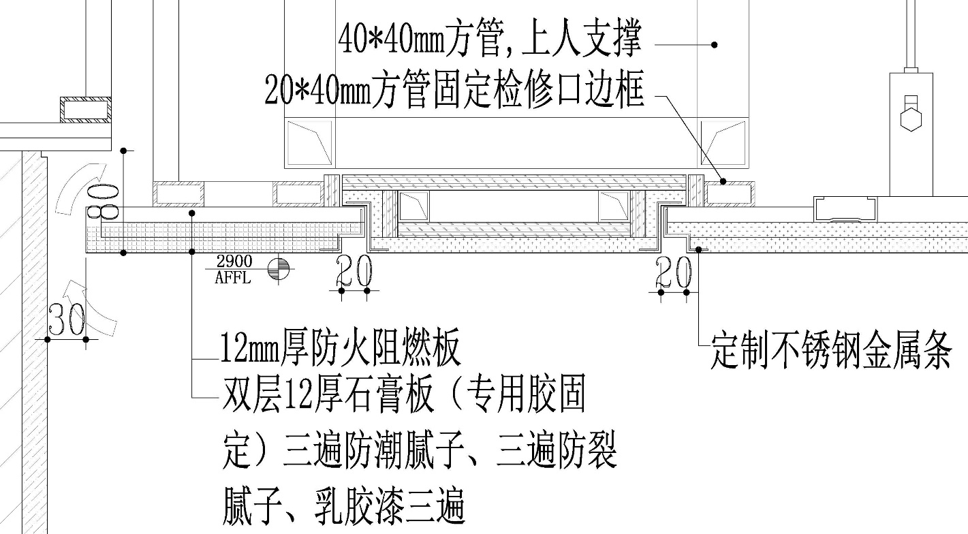

Overhaul the port practice

Deep processing adjustment: In the construction process, for the order or arrival of goods, found errors, gaps, modifications, and replacement orders.

Visa drawings: In the construction process, collect design changes, negotiations involved in the site photos, timely drawing drawings, in preparation for completion drawings. According to the drawing catalog, the regional drawings are perfected, and the nodes in the process are added to the corresponding areas and summarized.

Tip: As-built drawings – Construction drawings – Visa drawings

2.7

Deepen the work in the middle and late stages

Product integration: refers to the transformation from on-site construction to plant unit production, product construction management concept. Specifically for the scene to do a piece, finish a piece, acceptance of a piece, packaging a piece. Consider the material’s closing problem, easy installation management, construction process to monitor and track manufacturers, timely adjustment of development issues, stone, wood finish centralized production, group installation

Waste material inspection, large-scale selection, factory layout

Finished product packaging, construction installation, packaging acceptance ☟

Closing adjustment: during the construction process, the site exposed new problems, with upstream design, owners, and manufacturers to communicate, timely adjustment.

Before deepening, after deepening

2.8

Product integration phase

Details correction: on-site details of the problem, responsible for rectification, form a written form, confirm the rectification time and program.

Finished product positioning review: Review and correct the endpoint installation promptly to ensure overall results.

Waste into treasure: due to inadequate consideration of the pre-design, construction order errors, resulting in some material waste, in the late construction process, find ways from new use, to minimize losses.

Cooperate with accounting: cooperate with the budgeter to carry out the site drawings to supplement and modify, to facilitate the completion of the project final accounts.

Completion drawing finishing: with the project department to arrange covert acceptance slips, project contact slips, visa slips, meeting minutes, design change orders, according to the requirements of the budget staff to meet the operating requirements.

2.9

Deepen the final phase of work

Finished product installation: cooperate with the project department, do a good job of finished product protection, for the location of art emissions, reference to the construction drawings for guidance.

As-built drawing preparation: based on construction drawings, combined with change drawings.

Material finishing: sorting out the sample archive of upstream design confirmation.

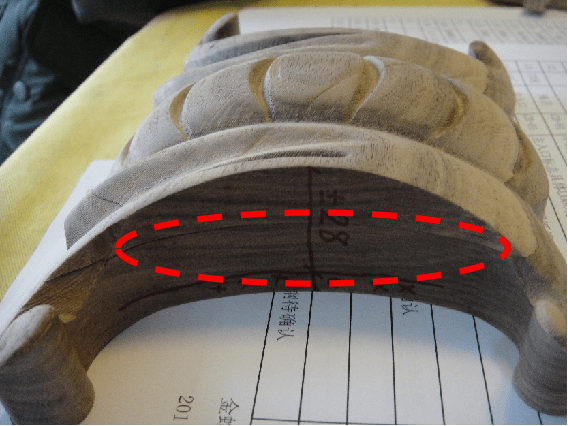

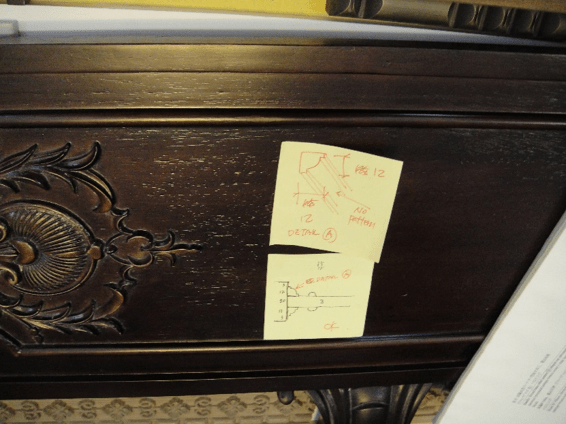

Walnut carvings are thinner

Border 15mm wide line changed to 13mm wide

Data collation: submit the completed plan to the project department.

Submission of the complete plan: sun map, stamp, signature, supervision signature seal, owner signature seal.

Deepening design is a bridge between the designer’s design language and the project construction landing, which is the most important link between design and engineering to ensure quality, schedule, and cost.