Aluminum mold and steel support wood mold system, are commonly used at this stage of the new support mold system, is to achieve the main structure of fine construction measures, effectively improve the quality of structural molding. Under such a system, how should the mechanical and electrical installation be combined with civil construction, but also achieve fine construction? The following engineering example from the electrical and water supply and drainage two aspects, sharing the display of aluminum mold and steel support wood mold system, mechanical and electrical installation of the construction process.

Electrical section

1

Drawing optimization

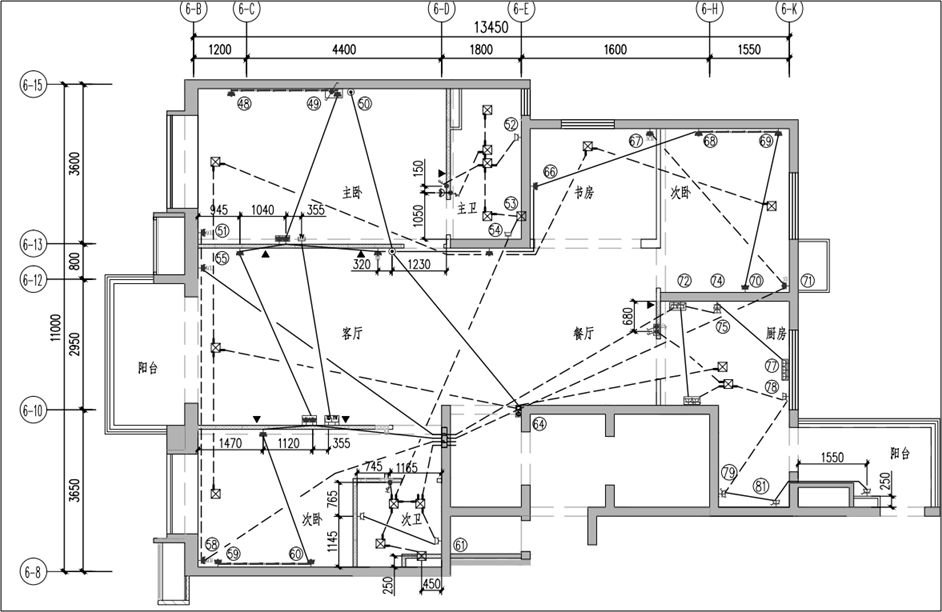

Indoor lighting line optimization

· Combine decorative drawings for precise positioning

· Lighting lines go to the ceiling for pre-buried

· Fire smoke line walk ceiling pre-buried

In-house socket line optimization

· Combine decorative drawings for precise positioning

· Air conditioning hang-up socket line go ceiling pre-buried

· Other socket lines Walk the floor pre-buried

· Weak power lines all go down the floor of the building pre-buried

Point optimization of lamps, smoke, etc. in public areas

· According to the width of the aisle center arrangement, the beam is equal

· Induction switch should be 300mm from the lamp arrangement, smoke spray and lamp spacing should be 500mm

The layout of the wells is optimized

· Wells should be set in conjunction with building floor plans and consider access space

Custom bridge reservation hole template

Well reserved hole template installation

Bridge installation effect

2

The wire box is pre-buried

Examples of frequently asked questions

The mold rate is insufficient, and the large area rectification in the later period

The installation method is uncontrolled and the bias is serious

Example of construction practices

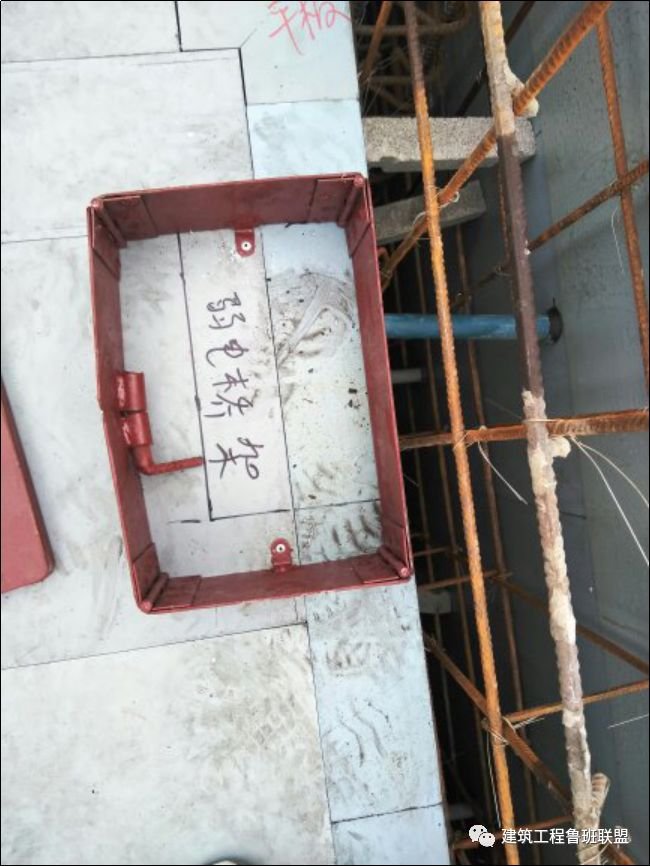

· Backbox installation procedures and protection

Install the cup comb connector

The box is filled with sawdust and compacted

Add protective cover wrapped tape protection

The rebar makes a fixed frame

· Precise positioning according to design drawings

Review the floor elevation baseline, with the help of laser leveling for accurate positioning, the processed back box is firmly tied (welded) on the positioning point.

Mark the floor elevation baseline

The laser level is positioned

Vertical, horizontal correction

· The back box is mounted fixed

Wearing a ribbed back box tie or welding fixing:

Aluminium-molded back box fixing:

The backbox is positioned and opened on the aluminum mold

Adjust the backbox position

Secure the bottom box with a self-tapping screw

· Shear wall pre-buried back box installation molding effect

Pre-buried molding effect of the rib back box

Aluminum mold bottom box pre-buried molding effect

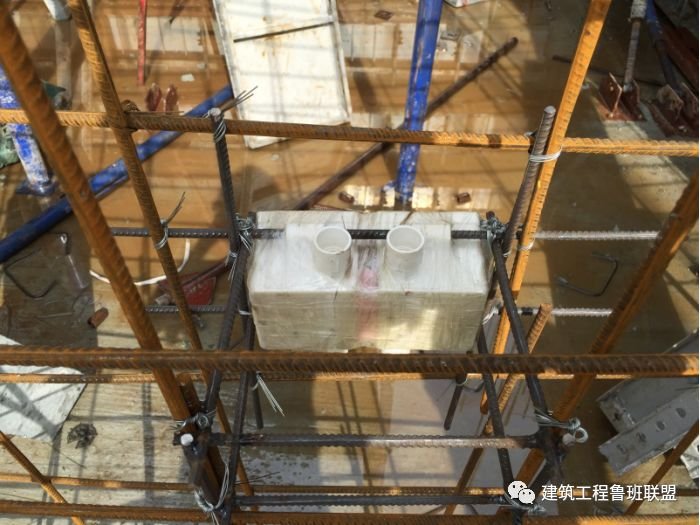

· The floor interior box is pre-buried

(1) Aluminum mold system pre-buried

Line positioning

Position the rubber block fixed to the template

The wire box is fixed

The tube is connected

(2)Steel support wood mold system pre-buried

3

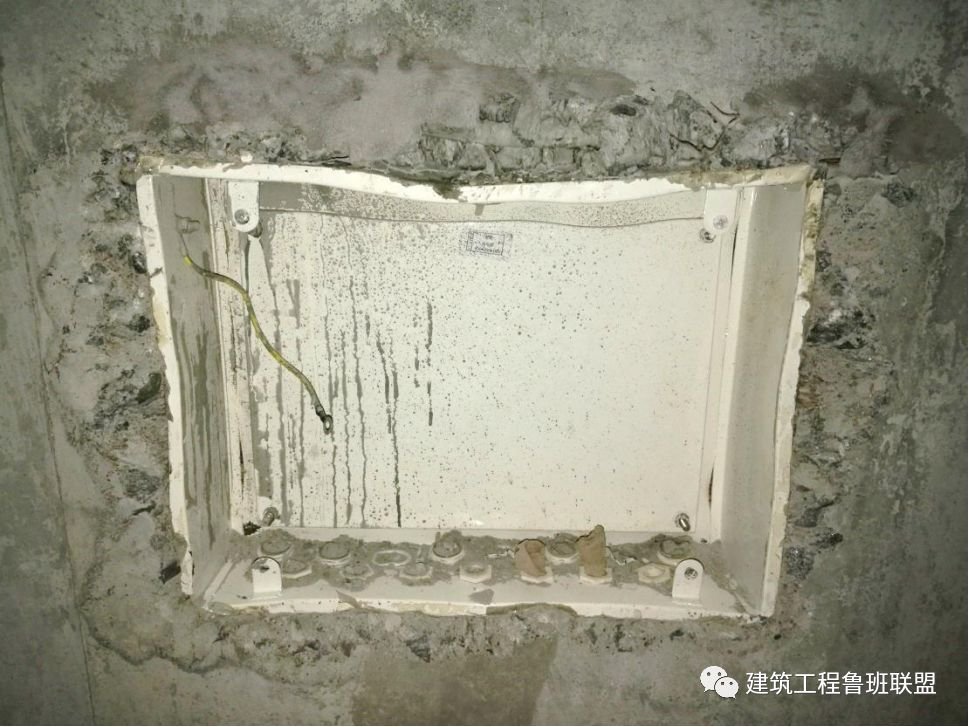

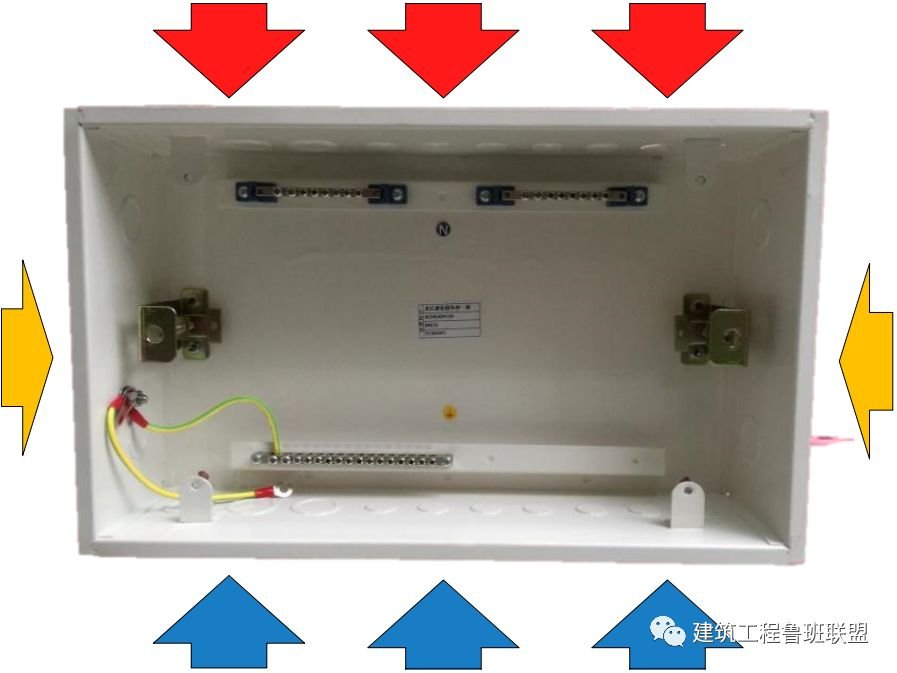

Strong and weak electric boxes are pre-buried

Examples of frequently asked questions

No pressure, anti-floating, molding, and other technical measures

The pre-buried electric box is subject to a sign of force

Example of construction practices

· There are several ways to reinforce the inside of the box

Fill the sawdust support

Use wooden support

Support with top support and plank

· The external reinforcement of the box

· On-site installation

· Install the molding effect

4

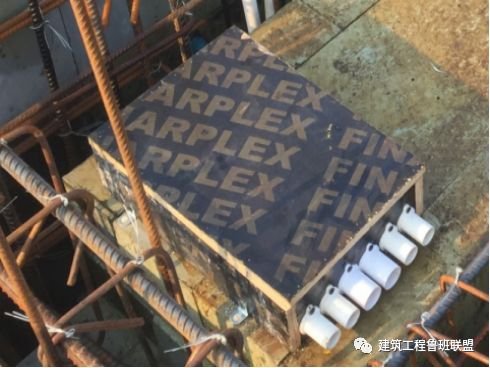

The good reserves holes

Examples of frequently asked questions

The well was not poured once with the floor

Example of construction practices

· Use a dedicated mold to synchronize reservations

5

PVC wire tube pre-buried

Examples of frequently asked questions

The arrangement is chaotic, stacked and the pipe spacing is unreasonable

There is no reinforcement protection at the connector point

Example of construction practices

· PVC line tube selection

PVC electrician casing is divided into light, medium, and heavy-duty, for floor and shear wall pre-buried pipe recommended to use all heavy PVC pipe(405 specifications), common specifications related parameters as shown in the table below.

· PVC line tube bending operation

Note:

(1) Select a special spring elbow by wire tube diameter

(2) The bending radius of the line pipe must be greater than 6 times the outer diameter of the line tube

(3) Bending or breaking occurs when bending, it is strictly forbidden to use

Spring elbow

· PVC wire tube strapping fixing requirements

(1) When the wire pipe is laid vertically and horizontally, the wire tube is laid between the steel mesh, the wire is tied firmly with the steel bar (plate laying and bottom rib binding), and the two fixed points are not more than 1 meter apart when the wire pipe is unfixed.

(2) The wire box should not be surrounded by more than 0.3 meters, the ends of the fittings should not be greater than 0.2 meters should be fixed while noting that all wire fittings and pipes must be bonded with PVC glue.

(3) When the direction of the wire pipe laid on the wall is not vertical, special reinforcement treatment shall be carried out in the fitting position to avoid damage when pouring concrete, as shown in the following illustration, adding a short pipe at the fitting and tying it together with the pre-buried pipe for reinforcement.

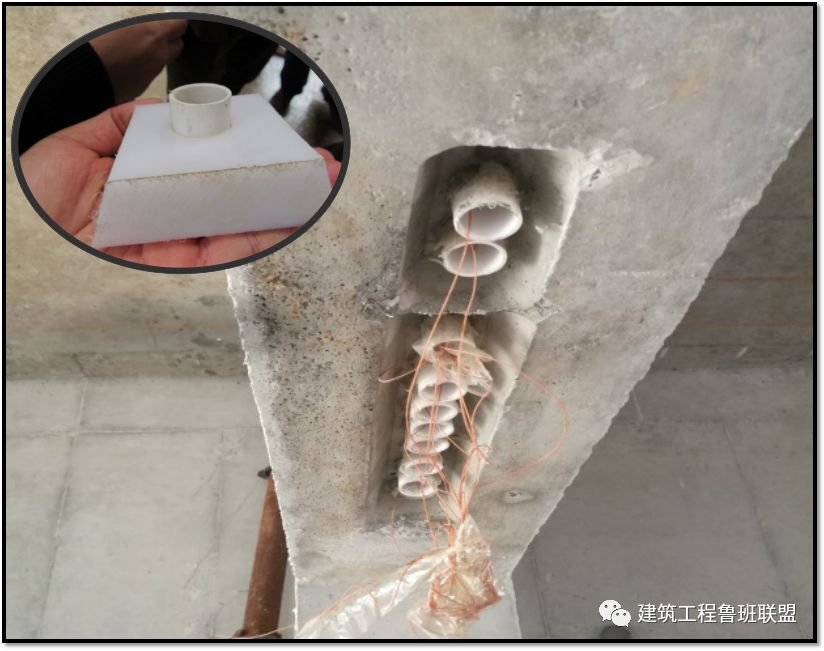

· PVC line pipe on the pipe opening sealing and positioning

Inappropriate practices:

shortcoming:

(1)Trouble with the operation

(2)There is a risk of pipe blocking

(3) The positioning of the line tube is not accurate

Recommended practices:

merit:

(1) Is easy to operate

(2) The seal is tight and there is no risk of blocking the pipe

(3)to ensure accurate positioning of the line pipe

· Shear wall pre-buried back box installation molding effect

The diameter of the hole in the plastic positioning block is the direct outer diameter of the corresponding wire tube

Rubber mold diameter according to the corresponding specifications of the direct size of the line tube to make

Water supply and drainage

1

Drawing optimization

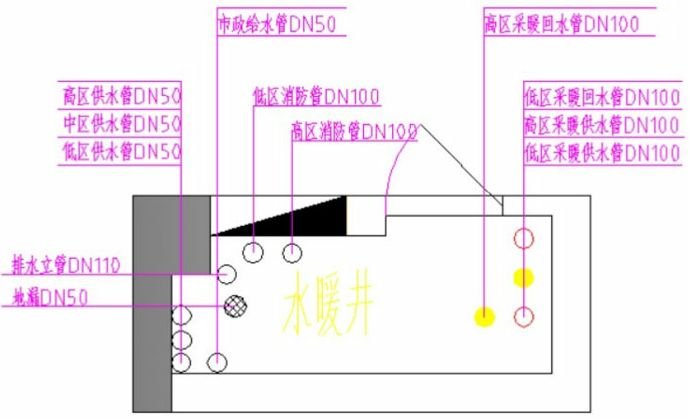

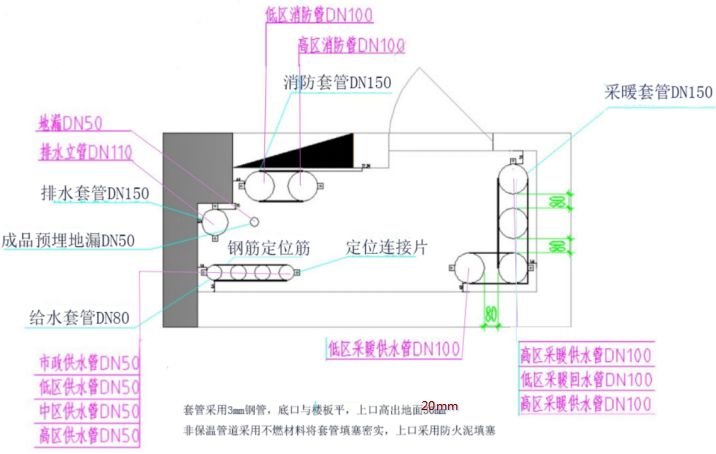

Pipeline well-drawing optimization

Original map of pipe well design

Pipeline well optimization layout

Casing installation requirements

· Installation requirements

1, steel casing should be 20mmhigher than the complete surface of the building.

2, steel casing thickness should be ≥ 2mm, casing brush primer, face paints each together to prevent rust.

3, the hot water pipe in the well should be following the design requirements to do a good job of insulation, insulation pipe bracket should be fortified with cold bridge measures.

The optimized installation effect

2

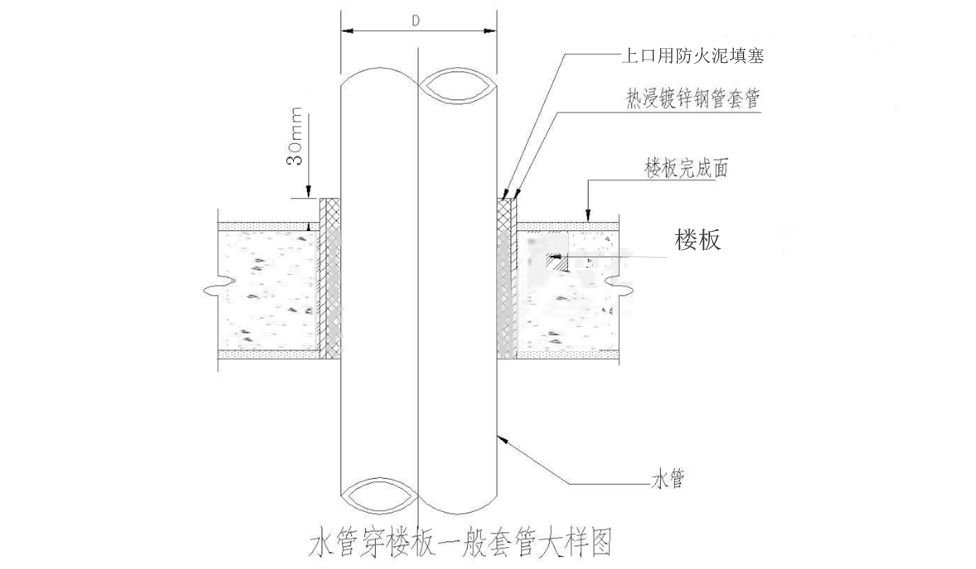

Casing pre-buried

Examples of frequently asked questions

Not reserved as per specification

Weld directly with structural ribs

Example of construction practices

· Horizontal direction sleeve

Steel support wood mold:

Position the mold

Combined casing processing and installation

Install the molding effect

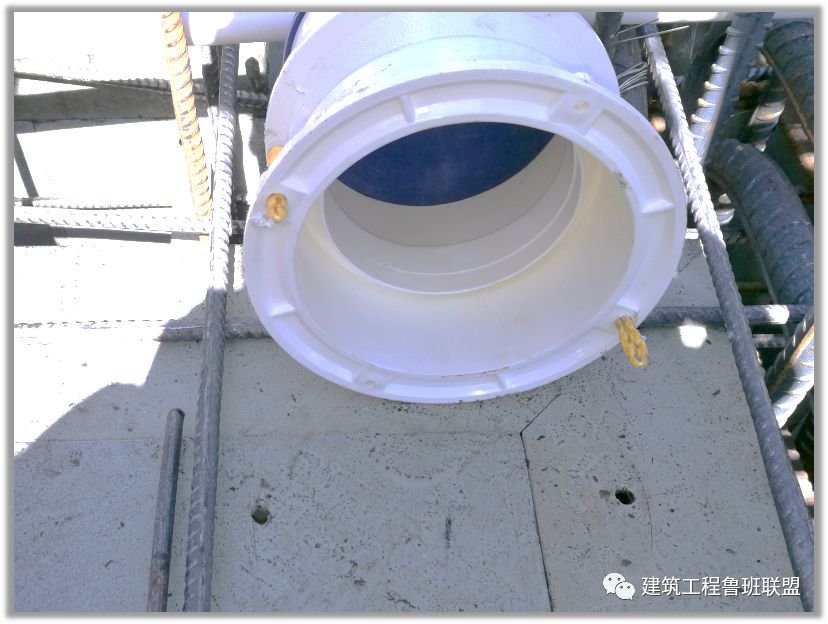

Aluminum mold:

Combined casing processing and installation

Install the molding effect

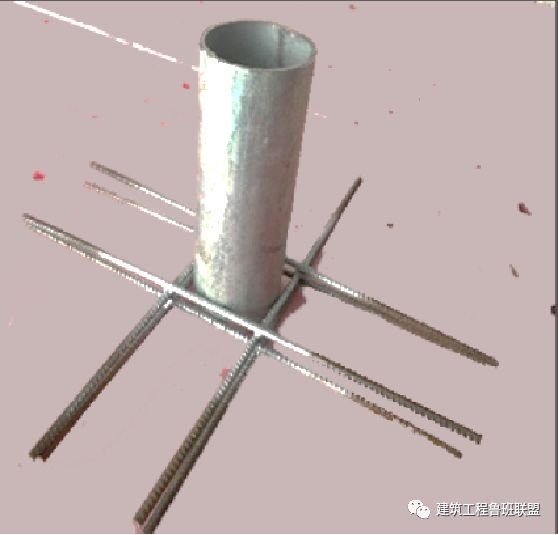

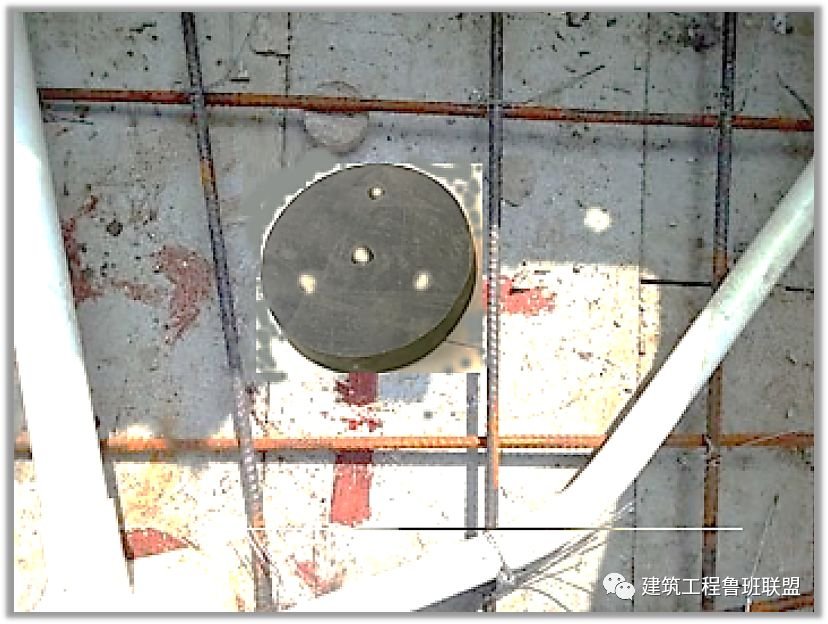

· Vertical casing

Well, glyph fixation method:

U-shape fixation method:

· Beam inner sleeve

Hanger fixing method:

3

Shear wall to install the water pipe

Examples of frequently asked questions

· Water pipes shall not be placed directly in the structural layers of buildings

Water pipes, whether they are metal or plastic (including composite pipes), shall not be directly buried in the structural layer of the building. If you must bury, you must set the casing outside the tube.

Example of construction practices

· The extruded plate is fixed to the rebar to leave a groove

Not recommended

· Steel mold slot

· Leave a groove in the water pipe structure

4

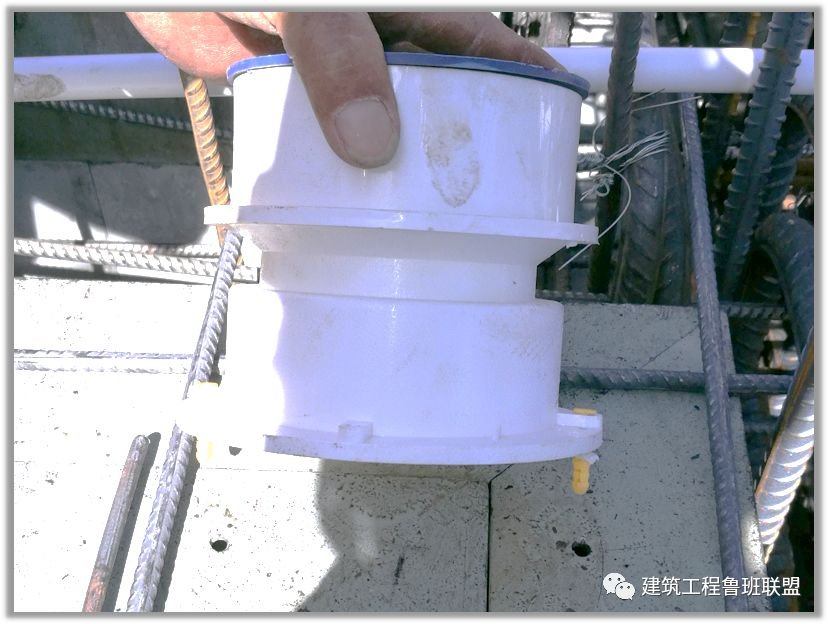

Drainpipe parts pre-buried installation

Examples of frequently asked questions

The fixation and blocking effect is not good

Example of construction practices

· Screw fixation method

· Screw-fixing method

· The glue fixation method

· Wood-mold fixation